Battery Science

At Process-ED, we provide consultancy expertise to the rapidly evolving battery development sector. With the global push toward electrification and sustainable energy solutions, the need for advanced, efficient, and commercially viable battery technologies has never been greater.

Our strength lies in bridging the gap between fundamental research and industrial application. We collaborate with world-leading academic institutions to bring cutting-edge scientific understanding into practical, scalable solutions for manufacturers, investors, and technology developers.

Academic Partnerships

We have strong relationships with:

- University College London (UCL) – Chemical Engineering Department

- University of Nottingham – Chemistry Department

Both institutions are internationally recognised for their pioneering work in energy storage materials and electrochemical engineering.

Our activities in this area are coordinated with Dr Alexander Kibler, an Assistant Professor in Electrochemical Systems in the cutting-edge Advanced Propulsion Laboratory (APL) at UCL. There, he specialises in the design and manufacture of next-generation batteries. Combined with Process-ED’s process knowledge, this means we have expertise spanning materials development, cell design, diagnostics, operando analysis and an in-depth understanding of relevant scale-up considerations. By bringing together academia and industrial consultancy, this enables us to combine state-of-the-art research with real-world engineering and commercial insight.

Services Offered

We support organisations across the full spectrum of battery innovation — from concept to manufacturing scale-up:

- Technology Feasibility Studies

Independent assessments of emerging battery technologies, evaluating technical and commercial viability. We help clients identify opportunities, risks, and realistic development pathways. - Process Design

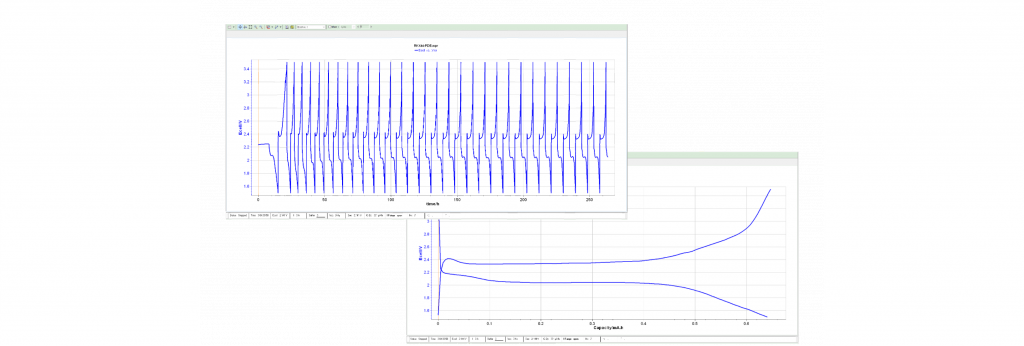

Expertise in the design of systems for processing battery materials, from raw feed treatment through to the recycling of cells. - Battery Diagnostics

Insight into battery ageing and failure mechanisms through analytical techniques, spanning chemical and mechanical degradation pathways from the nano- to the macro-scale. - Manufacturing Optimisation

Guidance on scaling laboratory concepts to pilot and industrial-scale production. We focus on process optimisation, cost reduction, quality control, and yield improvement. - Project Management of Battery Development

End-to-end coordination of battery R&D projects, ensuring alignment between technical objectives, timescales and budget. - Industrial–Academic Collaborations

Facilitating and managing collaborations between companies and academic research groups; enabling access to world-class facilities, expertise, and talent.

To learn more about our offering in the field of battery science and technology, please contact us at battery@process-ed.com