Xoptix – In-process Particle Size Analysis

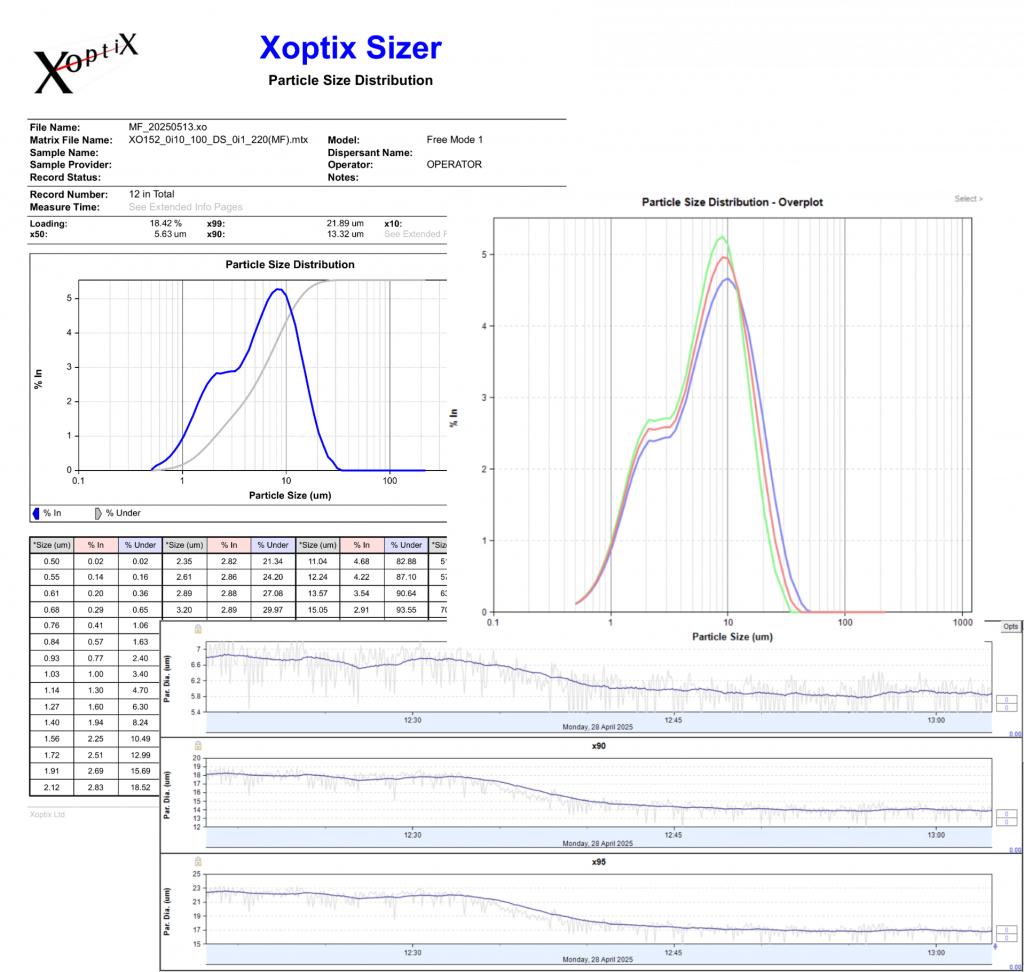

Xoptix manufactures a range of in-process particle size laser diffraction instruments that can truly transform system performance.

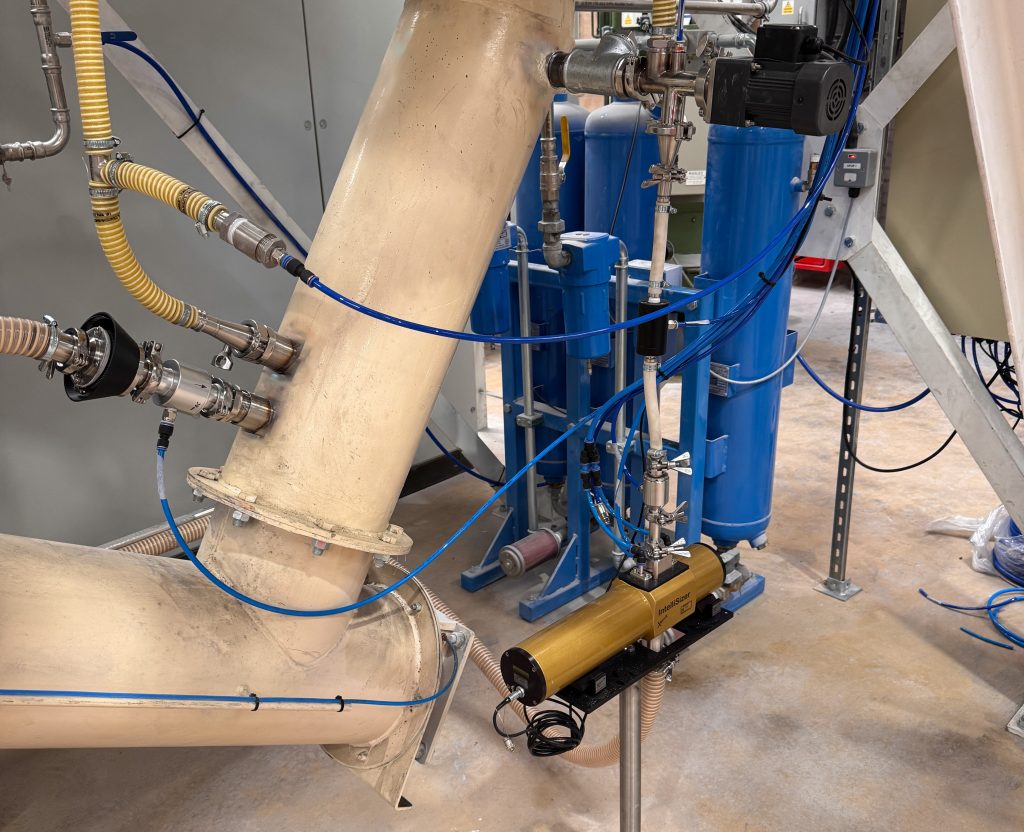

Designed and built in-house at their facility in Malvern, England, Xoptix developed the sizer specifically as a field instrument from the ground up. This approach enables them to offer one of the most advanced in-field particle sizers available, at a price significantly more affordable than competitors. In recent years, they have also introduced a variety of innovative sampling solutions tailored for diverse process environments—including gravity flow, pneumatic conveying, and locations with both positive or negative pressure: overcoming traditional challenges for in-process particle analysis.

In-process real-time particle size analysis allows for:

- Increase productivity by having the confidence to move closer to specification limits

- Lower energy costs by reducing the specific power consumption (kWh/tonne)

- Process variable feedstocks with a system that can automatically compensate by monitoring the PSD

- Greater level of quality control with 24/7 analysis and the ability to link production directly to PSD records

- Reduced reliance on laboratory staff and eliminate the need for operator sampling

Thanks to these benefits, our partnership with Xoptix plays a key role in our process optimisation services. Below you will find a short brochure showing what they offer. For more information, to explore how in-process particle size analysis can transform your operations, or to schedule an on-site demo, please contact us at sales@process-ed.com.